- Store

- >

- New

- >

- Rheometers & Viscometers & Flash Point Testers

- >

- Anton Paar

- >

- Anton Paar Rotational Viscometer ViscoQC 100 / 300

Anton Paar Rotational Viscometer ViscoQC 100 / 300

SKU:

$4,742.40

674.4

6576

$674.40 - $6,576.00

Unavailable

per item

The world’s most successful viscometers

Anton Paar Rotational Viscometer ViscoQC 100

Anton Paar Rotational Viscometer ViscoQC 300

| viscoqc_100-300_x.pdf | |

| File Size: | 928 kb |

| File Type: | |

-

Key Features

-

Technical Specifications

<

>

Unpack your digital viscometer and measure right away

The setup takes less than 2 minutes as ViscoQC comes pre-assembled when delivered, including a SOP booklet that introduces the first steps and simplifies user trainings. The built-in digital leveling automatically indicates correct leveling at start-up, before, during and after measurement which ensures highest accuracy. It prolongs the lifetime of your viscometer and reduces maintenance by protecting its bearings. For pharmaceutical customers, Anton Paar offers instrument qualification packages: ViscoQC is qualified and ready to use within one day by ensuring full compliance to 21 CFR Part 11, GMP, and GAMP 5 (ViscoQC 300 + V-Comply) or compliance to GMP, and GAMP 5 (ViscoQC 100).

The easiest way to measure dynamic viscosity

You do not need to be an expert to measure with ViscoQC. Anton Paar’s viscometers guide you through – from start-up to the entire measurement process – via the intuitive user interface. Continue to use your standard operating procedure (SOP) methods of your existing rotational viscometer as ViscoQC will give you the same results by using the same instrument setup and measuring settings. Each spindle is equipped with magnetic coupling for easy spindle exchange to save up to 15 seconds per test. This coupling also further reduces maintenance costs by protecting the spindle and instrument against damage caused by knocks or bending. All spindles from Anton Paar are made of chemically resistant stainless steel (AISI 316L), which increases spindle lifetime by protecting them from corrosion.

Full traceability for reliable viscosity tests

Be confident in your results as for fully traceable results ViscoQC instantly detects and documents the measuring setup of the following parts:

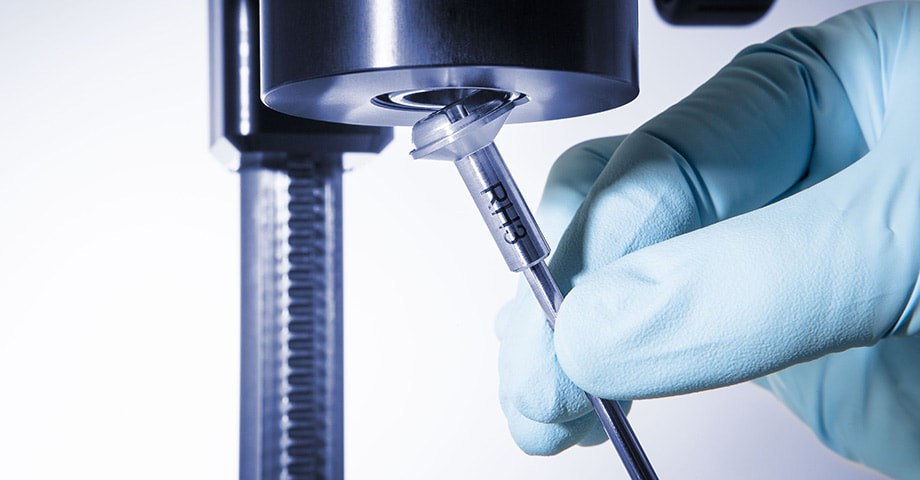

- Spindles by Toolmaster™ and spindle guard by TruGuard™

- Temperature devices and sensors (PTD 80, PTD 175, Pt100)

- Heli-Plus

The most convenient way to generate and export data in viscosity quality control

Every ViscoQC includes the V-Collect PC data collection software free of charge. As ViscoQC 100 does not store any data, results are directly exported to V-Collect or printed via the Dymo® LabelWriter™ after each test. ViscoQC 300 has a huge data memory for up to 999 measurements with up to 10,000 sub-measurements on 150 MB. Additionally it is possible to print and export data as PDF, CSV, or page printer (USB or network) to V-Collect and the Dymo® LabelWriter™. For automated data export, ViscoQC 300 can be integrated into your network via Laboratory Information Management System (LIMS) or FTP Server.

Whether you choose ViscoQC 100 or ViscoQC 300, these viscometers are future-proof as they grow with your evolving needs. To measure new paste-like formulations (e.g. wall putty), you can upgrade your instruments with the Heli-Plus and T-bar spindles. Gel time/pot life determination of e.g. adhesives is automatically possible with both models. If you need most accurate sample temperature control and have less than 20 mL of sample volume available, simply use the Peltier temperature device PTD 80. Further software functionality can be added to ViscoQC 300 with up to two optionally upgradeable software modules: V-Curve and/or V-Comply.

- V-Curve adds real-time graph, analysis (e.g. yield point), programmability, and extended method functionality (e.g. with PTD 175)

- V-Comply for compliance to 21 CFR Part 11 (e.g. audit trail, electronic signature), including qualification documentation

OPTIONAL ACCESSOIRES:

Temperature control solutions for ViscoQC, Temperature Devise PTD 80

Temperature control solutions for ViscoQC, Temperature Devise PTD 80

- For ViscoQC 100/300; viscometers and temperature device from a single source

- Air cooling ensures small footprint, and reduces maintenance costs

- Exact sample temperature control of, e.g. chocolate, adhesive

- For routine QC applications from +15 °C to +80 °C (±0.1 °C)

- Equips your density (and sound velocity) meter or viscometer for gesture-controlled operation

- Interact with your device without touching it, e.g. when your hands are dirty or wet

- Start and stop measurements, select methods, etc.

- Ensures your sample is always centered in the right place

- To easily center ½ pint, pint, quart containers, or 600 mL beakers

- Easily mounted on instrument stand

- Guarantees reproducible results

- Convenient operation thanks to motorized stand instead of manual height adjustment

- Measure paste-like materials (e.g. mayonnaise) with helical T-bar spindle movement

- Simplest spindle exchange saves up to 15 seconds per measurement

Worldwide support for your viscometer guaranteed – at any time

- Benefit from our exclusive extended three-year warranty program

- At-site exchangeable sensor for minimum downtime in case of repair

- Avoid manual wind-up procedure thanks to automatic bearing check by TruSine™

- A free installation and operational qualification document is included in every delivery

- Fast support ensured by Anton Paar's LiveChat

Viscosity Test |

Single point |

Multi-point |

Viscosity range [mPa.s] (depends on the measuring system) |

L - 1* to 6M R - 10** to 40M H*** to 320M |

L - 1* to 6M R - 3** to 40M H24*** to 320M |

Speed [rpm] |

0.1 to 200 25 increments: 19 standard speeds plus 6 freely selectable speeds |

0.01 to 250 Speed list with 18 standard speeds Freely selectable speeds within the speed range |

Max. spring torque [mNm] |

L - 0.0673 R - 0.7187 H - 5.7496 |

L - 0.0673 R - 0.7187 H - 5.7496 |

Accuracy |

±1.0 % full scale range |

+15 °C to + 80 °C (for DIN/SSA with PTD 80) -45 °C to +175 °C (for DIN/SSA/UL/4B2/L1D22 with PTD 175) |

Repeatability |

±0.2 % |

±0.2 % |

Display |

3.5” color LCD |

7” color touchscreen |

Data storage |

Non-storage Direct print/export |

Data memory for up to 999 measurements Print/export from data memory |

* With optional double-gap system DG26, with L1 spindle 15 mPa.s

** With optional double-gap system DG26, with RH1 spindle 100 mPa.s

*** With optional double-gap system DG26, with RH1 spindle 800 mPa.s

M=1 million

** With optional double-gap system DG26, with RH1 spindle 100 mPa.s

*** With optional double-gap system DG26, with RH1 spindle 800 mPa.s

M=1 million

-

L Model

-

R Model

-

H Model

<

>

Viscosity Ranges per Torque Model

Min. and max. viscosity are calculated values for L standard speeds (0.3 rpm to 60 rpm).

Spindle |

Min. viscosity [mPa.s] |

Max. viscosity [mPa.s] |

L1 |

15 |

20,000 |

L2 |

50 |

100,000 |

L3 |

200 |

400,000 |

L4 |

1,000 |

2,000,000 |

CC12 |

20 |

37,900 |

CC18 |

5 |

11,400 |

CC26 |

2 |

3,800 |

DG26 |

1 |

2,600 |

CC12/D18 |

70 |

100,000 |

SC4-18 |

5 |

10,000 |

SC4-21 |

10 |

15,500 |

SC4-27 |

40 |

78,000 |

Vane Spindles

Min. and max. viscosity are calculated values at 10 rpm.

Spindle |

Min. viscosity [mPa.s] |

Max. viscosity [mPa.s] |

V71 |

Not Recommended |

Not Recommended |

V72 |

104 |

1,040 |

V73 |

500 |

5,000 |

V74 |

5,090 |

50,900 |

V75 |

1,996 |

19,960 |

Viscosity ranges per torque model

Min. and max. viscosity are calculated values for RH standard speeds (0.5 rpm to 100 rpm, 0.3 rpm as min. for SC4-XY).

Spindle |

Min. viscosity [mPa.s] |

Max. viscosity [mPa.s] |

RH1 |

100 |

20,000 |

RH2 |

100 |

80,000 |

RH3 |

100 |

200,000 |

RH4 |

200 |

400,000 |

RH5 |

400 |

800,000 |

RH6 |

1,000 |

2,000,000 |

RH7 |

4,000 |

8,000,000 |

CC12 |

120 |

50,000 |

CC18 |

40 |

50,000 |

CC26 |

15 |

24,400 |

DG26 |

10 |

10,000 |

CC12/D18 |

440 |

100,000 |

SC4-18 |

30 |

100,000 |

SC4-21 |

50 |

100,000 |

SC4-27 |

250 |

200,000 |

Vane Spindles

Min. and max. viscosity are calculated values at 10 rpm.

Spindle |

Min. viscosity [mPa.s] |

Max. viscosity [mPa.s] |

V71 |

262 |

2,620 |

V72 |

1,110 |

11,100 |

V73 |

5,330 |

53,300 |

V74 |

54,300 |

543,000 |

V75 |

21,300 |

213,000 |

Viscosity ranges per torque model

Min. and max. viscosity are calculated values for RH standard speeds (0.5 rpm to 100 rpm, 0.3 rpm as min. for SC4-XY).

Spindle |

Min. viscosity [mPa.s] |

Max. viscosity [mPa.s] |

RH1 |

800 |

160,000 |

RH2 |

800 |

640,000 |

RH3 |

800 |

1,600,000 |

RH4 |

1,600 |

3,200,000 |

RH5 |

3,200 |

6,400,000 |

RH6 |

8,000 |

16,000,000 |

RH7 |

32,000 |

64,000,000 |

CC12 |

1,000 |

50,000 |

CC18 |

300 |

50,000 |

CC26 |

100 |

50,000 |

DG26 |

60 |

10,000 |

CC12/D18 |

3,500 |

100,000 |

SC4-18 |

250 |

50,000 |

SC4-21 |

400 |

100,000 |

SC4-27 |

2,000 |

200,000 |

Vane Spindles

Min. and max. viscosity are calculated values at 10 rpm.

Spindle |

Min. viscosity [mPa.s] |

Max. viscosity [mPa.s] |

V71 |

2,096 |

20,960 |

V72 |

8,880 |

88,800 |

V73 |

42,640 |

426,400 |

V74 |

434,400 |

4,344,000 |

V75 |

170,400 |

1,704,000 |